According to the World Health Organization, 1.8 billion people worldwide use a source of drinking water that is contaminated. By 2025, half the world’s population will live in water-stressed areas.

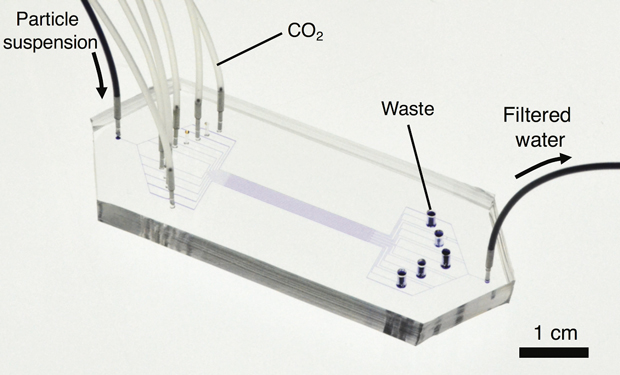

A team led by the University of Hawaiʻi at Mānoa’s Sangwoo Shin along with Orest Shardt of University of Limerick has found a promising, inexpensive way to clean water using carbon dioxide. Their study was published May 2017 in Nature Communications.

Shin, an assistant professor of mechanical engineering, said, “Just like making a soda, adding CO2 to a cup of water can be a powerful way to remove suspended particles.”

The study notes that typical water purification technologies, such as microfiltration and reverse osmosis, use porous membranes to remove particles and solutes. The membranes have high pumping costs and need periodic replacement.

The researchers say exposure to carbon dioxide causes particles in water to move away or toward the gas, depending upon the particle’s surface charge. Directing the particles using the gas is scalable and exhibits three orders of magnitude less energy consumption than conventional water filtering processes.

Shin says the next step is to scale the system for possible use in households or water treatment plants to supply larger communities, which requires further engineering design and optimization.

For the full article, see Nature Communications.

—By Kelli Trifonovitch