A group of volunteers led by two University of Hawaiʻi at Mānoa PhD students are creating sewing kits for cloth masks designed for people to wear as a preemptive measure against possible asymptomatic transmission of COVID-19.

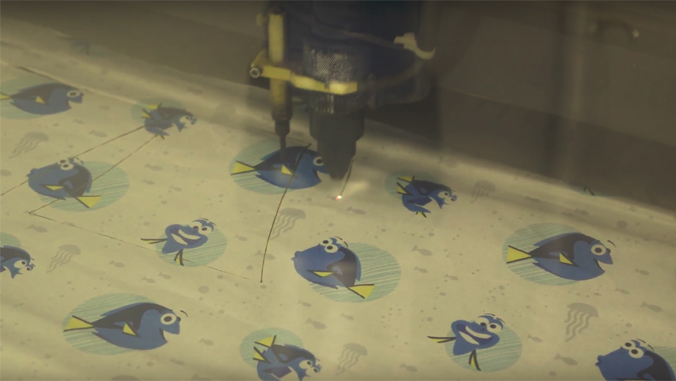

Sergey Negrashov and Chris Ketter established Aloha Mask, to create the kits with fabric to produce a double-ply cloth mask, through the College of Engineering’s FabLab, a self-sustaining space designed for students to fabricate their designs. Negrashov said it would take a person about 15 minutes to sew the mask with a sewing machine.

Negrashov, a computer science student who recently passed his dissertation defense, works full-time as an applied physicist at Oceanit. Ketter is a physics student.

“The universal shortage of personal protective equipment across the world has driven a lot of people to do what they can to help people on the front line fighting this disease,” Negrashov said. “I tried my hand sewing the masks from available patterns and found that most of my time was spent cutting the patterns. Our innovation is using the FabLab laser cutter to mass produce mask kits for volunteers with sewing machines to assemble and donate to any organization that needs them.”

Negrashov’s goal is to make 400 masks per day for all types of frontline workers, as long as they can continue to secure materials. The current version of the mask is designed to contain the virus and protect others if the wearer is ill. He eventually hopes to design a mask to protect healthy individuals from getting sick.

“Current research suggests that the best material for masks is cotton,” Negrashov said. “We will be pivoting our production towards a new mask design with a pocket for a filter commonly used in hospitals. Those will go directly to healthcare workers.”

Negrashov and Ketter are working with Oceanit and are planning to collaborate with researchers in the UH Mānoa oceanography department to test the effectiveness of their filter designs. Once team members identify the best filter material, they will retool their manufacturing.

How to help

The effort is funded by Negrashov and his co-workers at Oceanit. They are not looking for monetary donations right now. However, they are in desperate need of fabric and people willing to assemble the kits they produce.

More information on how to volunteer, donate fabric and instructions for assembling the kits.

—By Marc Arakaki